Modern Emergency Disinfection Units (EDUs) are vital in protecting people from biological pathogens. When Evergreen UV, a Tennessee-based leader in UV air disinfection technologies, needed to redesign its EDU, the company adopted PanelPilot’s touchscreen HMI platform.

The aim was to move away from unreliable manual timers and introduce a digital control solution that offered improved reliability, better disinfection monitoring and greater ease of use.

The Challenge with Traditional Timers

Manual timers had become a significant weakness in Evergreen UV’s EDU. They were difficult to operate, prone to inaccuracy and degraded in performance over time.

Derrick Sears, CTO at Evergreen UV, explained:

[The traditional, manual timers] were both very hard to set and their accuracy would diminish.

The new design required a smarter system that could monitor sensors, log data and raise alarms to ensure effective and safe operation.

PanelPilotACE as the Solution

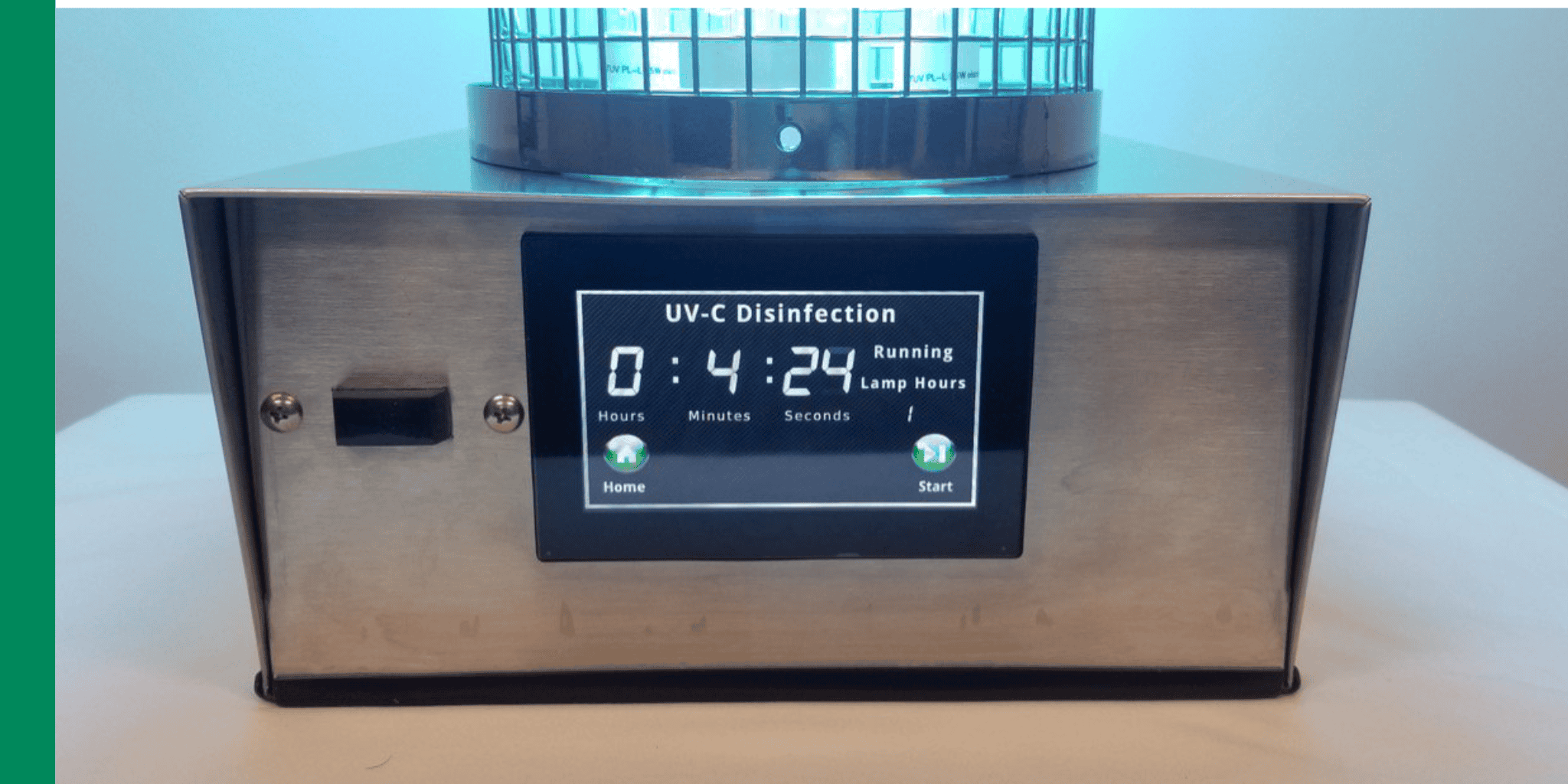

Evergreen UV selected the 4.3” PanelPilotACE display for its Emergency Disinfection Units, describing it as the most important part of the design. A larger 7” version is also available for systems that require a bigger interface.

The display allows operators to:

- Set delayed start times

- Adjust run durations with accuracy

- Automatically log operational data for disinfection monitoring

- Receive alerts when UV lamps approach end-of-life

This transformation gave the Emergency Disinfection Units a more responsive and user-friendly interface, making it far more effective for UV air disinfection.

PanelPilotACE Design Studio Speeds Development

The introduction of PanelPilotACE Design Studio was just as important as the hardware itself. The free software package enables engineers to create multi-screen interfaces using drag-and-drop tools, without the need for coding knowledge.

For Evergreen UV, the benefits were significant:

- Faster development across eight different design versions

- Easier prototyping of features such as motion sensor monitoring and alarms

- Quick integration of new functionality into additional product lines

This reduction in development time meant Evergreen UV could deliver more reliable disinfection technology in a fraction of the time.

Applications Beyond Emergency Disinfection Units

The PanelPilotACE display quickly found use in other Evergreen UV projects. In one case, it was used to manage eight independent UV bulb sets. The PID control display balanced usage across all bulbs, ensured consistent burn times and notified users when maintenance or replacement was required.

This provided longer component life and improved reliability across Evergreen’s wider range of UV air disinfection products.

Designed for Complex Control Systems

To support more advanced applications, the SGD 70-A, a PanelPilotACE-compatible display, provides a wide range of input and communication options:

- 4 x 16-bit bipolar analogue inputs

- 8 x digital input/output pins

- 2 x alarm outputs

- 4 x PWM outputs

- RS232, RS485 and CANbus communication

- FTP file transfer over Ethernet

These features allow seamless integration into both Emergency Disinfection Units and other industrial disinfection equipment.

Smarter Disinfection for Safer Environments

By integrating PanelPilot’s programmable displays into its Emergency Disinfection Units, Evergreen UV achieved:

- More reliable UV air disinfection

- Reduced downtime and maintenance

- Faster product development

- Improved operator safety with alarms and notifications

As Evergreen UV’s CTO described, the PanelPilotACE display is now the most important part of their disinfection systems, providing a flexible and dependable solution wherever performance and safety are essential.