In March 2020, as the Covid-19 crisis escalated in the UK, Oxford Optronix was invited to join a consortium tasked with supplying critical medical equipment to the NHS. The mission was clear: design and deliver a reliable oxygen monitor for continuous Positive Airway Pressure (cPAP) devices in just five days.

cPAP systems were vital for treating Covid-19 patients with respiratory issues, yet in short supply across hospitals. A compact, accurate oxygen concentration monitor was urgently required to provide continuous readings and trigger alarms if levels deviated from safe thresholds. Normally, developing such a device would take years, but in this emergency there was no time for standard processes.

A Call That Changed Everything

Dr Andy Obeid, CEO of Oxford Optronix, recalled the moment:

On 21st March, I received an urgent call from Professor Mervyn Singer of University College London Hospital explaining to me the vital importance of cPAP in supporting COVID-19 patients with breathing difficulties, especially in those cases where conventional ventilation isn’t justified or potentially injurious to the patient.

Minutes later, I was being quizzed on how to design, develop and manufacture a monitor to continuously measure the concentration of oxygen being delivered to the patient via cPAP. I soon realised that Mervyn was politely asking me to do something in five days that would normally take two years.

The Oxford Optronix team quickly defined the requirements. The cPAP oxygen monitor needed a touchscreen display for real-time oxygen levels and the ability to set alarm thresholds. Typically, sourcing the display, coding the interface, and integrating it with sensors would take months.

Enter PanelPilotACE

Oxford Optronix already had experience with the PanelPilotACE display platform. This all-in-one touchscreen solution provided both the interface and processing power required for a fast-track development project.

The companion software, PanelPilotACE Design Studio, eliminated the need for coding. Using drag-and-drop tools and pre-built modules, engineers could design the interface within hours. The oxygen sensor’s 4–20 mA signal was connected directly to the display, creating a seamless integration.

I knew we needed something that would enable us to design and build a touchscreen interface, with process control, in under a week. PanelPilotACE was that product.”

– Stephen Douglas, Technical Director, Oxford Optronix

Collaborative Innovation Under Pressure

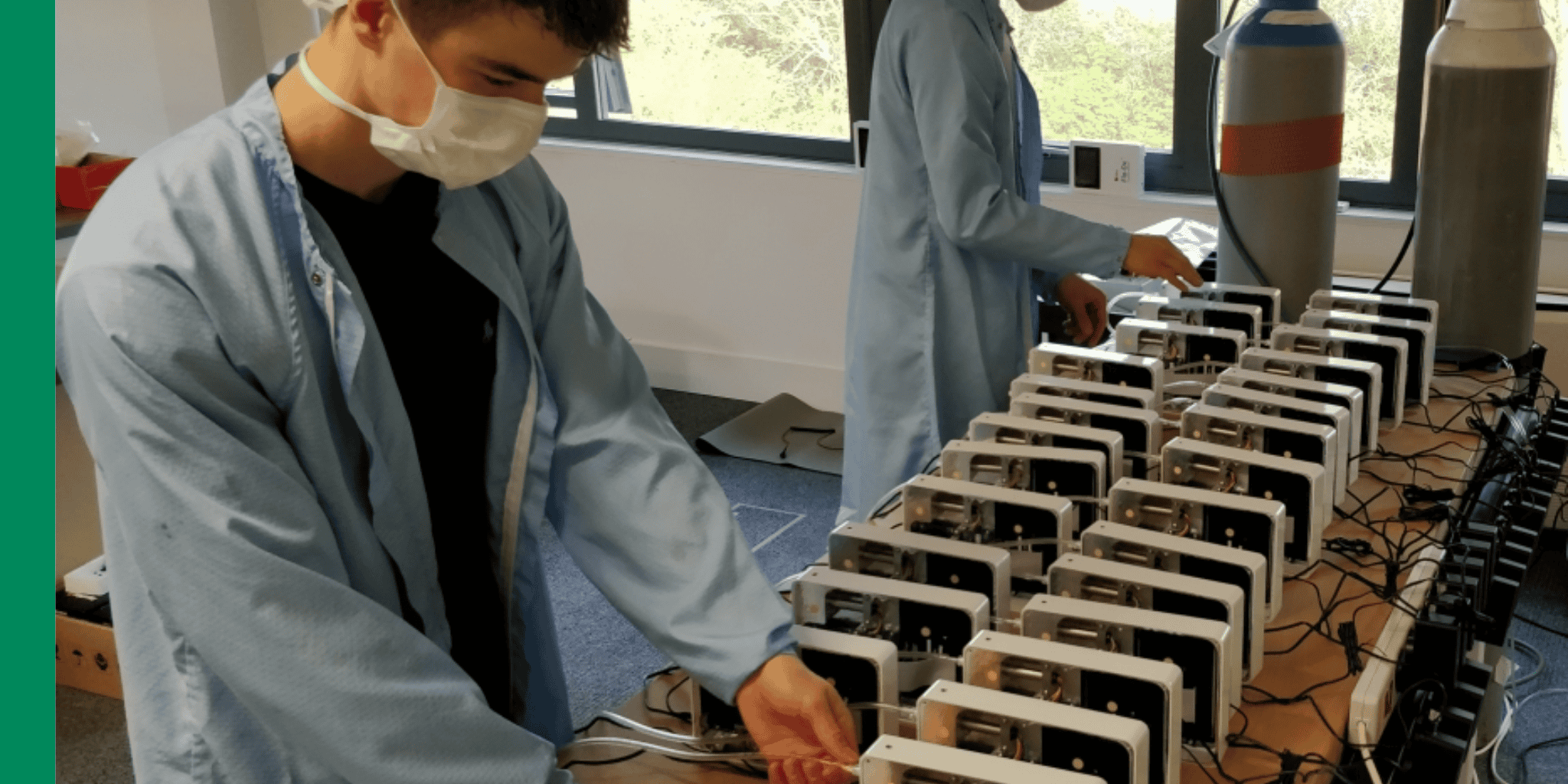

With technical support from PanelPilot, the Oxford Optronix engineers quickly built a prototype. Just one week after the initial phone call, the first Flo-Ox oxygen monitors were in testing.

Meanwhile, other elements of the cPAP device were being developed by Mercedes-AMG High Performance Powertrains and University College London. Together, the consortium combined medical expertise and cutting-edge engineering to deliver a lifesaving solution at record speed.

Mission Accomplished

Thanks to around-the-clock work and total team commitment, Oxford Optronix delivered 2,000 Flo-Ox cPAP oxygen monitors to the NHS in only eight days. The achievement demonstrated how fast-track development and collaborative innovation can save lives during a crisis.

Well, we did it.”

– Dr Andy Obeid